Ideal for All Types of Warehouses and Businesses

Maximize Efficiency and Safety in Your Warehouse with Reliable Material Handling Equipments

Tired of Slow, Inefficient Operations That Hurt Your Bottom Line

Are you frustrated with sluggish processes and inefficiencies that are affecting your company’s profitability? Slow operations not only waste valuable time but also drain resources, reduce productivity, and hinder growth.

Increased Operational Costs

Traditional methods of handling materials may require more employees or more time, leading to higher costs.

Inefficient Operations

Many businesses struggle with inefficient manual labor or outdated equipment, leading to slower processes, bottlenecks, and increased labor costs.

Safety Concern

Improper material handling can lead to workplace injuries, costly accidents, and even legal liabilities.

Lack of Space Optimization

With limited warehouse or factory space, businesses often struggle with inventory management and need better systems for storing and retrieving goods efficiently.

Scalability Challenges

As companies grow, your existing material handling infrastructure may no longer meet the demands of larger inventory or more complex operations

Supply Chain Disruptions

Whether due to labor shortages, raw material delays, or equipment failure, can severely impact a company’s ability to meet deadlines and customer expectations.

Optimize Your Business with Equipment That Meets Your Exact Needs

Every business operates differently, and your material handling equipment should work for you, not the other way around. These equipment is perfectly fit the specific needs of your business, boosting efficiency, reducing downtime, and enhancing safety.

Hand Pallet Jack

1.0 - 5.0 Ton

Submit your inquiry for material handling equipment.

Hand Truck | Trolley

150 kg - 500 kg

Submit your inquiry for material handling equipment.

Stacker

150 kg - 2.0 Ton

Submit your inquiry for material handling equipment.

Ladder Trolley

Up to 200 kg

Submit your inquiry for material handling equipment.

Lift Table

150 kg - 2.0 Ton

Submit your inquiry for material handling equipment.

Drum Equipment

360 kg - 500 kg

Submit your inquiry for material handling equipment.

Order Picker

1.0 - 2.0 Ton

Submit your inquiry for material handling equipment.

Fork Extension

1.0 - 2.0 Ton

Submit your inquiry for material handling equipment.

Hand Pallet Jack

1.0 - 5.0 Ton

Submit your inquiry for material handling equipment.

Hand Truck | Trolley

150 kg - 500 kg

Submit your inquiry for material handling equipment.

Stacker

150 kg - 2.0 Ton

Submit your inquiry for material handling equipment.

Ladder Trolley

Up to 200 kg

Submit your inquiry for material handling equipment.

Lift Table

150 kg - 2.0 Ton

Submit your inquiry for material handling equipment.

Order Picker

1.0 - 2.0 Ton

Submit your inquiry for material handling equipment.

Drum Equipment

360 kg - 500 kg

Submit your inquiry for material handling equipment.

Fork Extension

1.0 - 5.0 Ton

Submit your inquiry for material handling equipment.

We are Serving a Wide Range of Industries

From manufacturing and warehousing to retail and logistics, our equipment helps businesses optimize operations, improve safety, and drive efficiency. No matter the industry, we’re committed to delivering high-quality solutions that support growth and enhance productivity.

Retail Stores

Petrochemicals

Shipping & Freight

Tiles Manufacturer

Rubber Manufacturer

Steel Manufacturer

Food Manufacturer

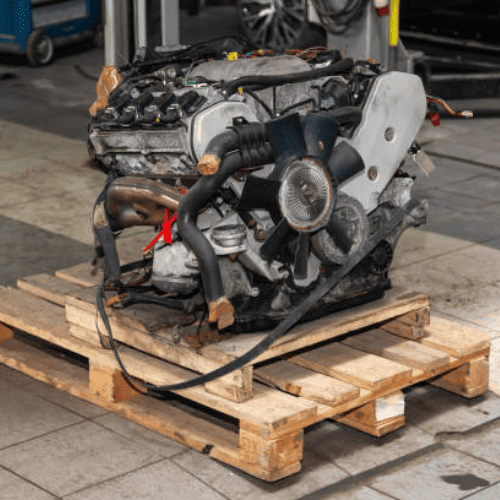

Automotive

Pallet Manufacturer

Our Clients Who Trust Us

From improving efficiency to ensuring safety, our clients experience significant gains in productivity and cost savings. We’ve built long-lasting partnerships by providing high-quality, reliable equipment, exceptional customer support, maintenance services, and spare parts.

Customer Support

Repair & Maintenance

Spare-Parts

Why Choose Us

Large Inventory

We keep over 1,000 pallet trucks in stock every day.

Custom Modifications

We can adjust equipment to meet your specific needs.

Expert Advice

We help customers choose the best equipment to boost efficiency.

Complete Spare Parts

We provide all necessary spare parts for our equipment.

Cost Savings

We offer advice to reduce repair and breakdown costs.

Buy-Back Guarantee

We guarantee to buy back your equipment in the future.

Large Inventory

We keep over 1,000 pallet trucks in stock every day.

Custom Modifications

We can adjust equipment to meet your specific needs.

Expert Advice

We help customers choose the best equipment to boost efficiency.

Complete Spare Parts

We provide all necessary spare parts for our equipment.

Cost Savings

We offer advice to reduce repair and breakdown costs.

Buy-Back Guarantee

We guarantee to buy back your equipment in the future.

Frequent Question & Answered

- Pallet trucks are used for moving pallets short distances, primarily on flat surfaces. They allow workers to lift pallets off the ground and move them around efficiently.

- Stackers, on the other hand, are designed for lifting pallets to higher levels, allowing for stacking and shelving. They are ideal for storing goods in racks or higher shelves in warehouses.

When selecting a pallet truck, consider factors like load capacity, fork length, and the type of surface you’ll be using it on. If you’re handling heavy loads, a high-capacity model is necessary.

Yes, we offer comprehensive repair and maintenance services for all types of pallet trucks and stackers. Our expert technicians can handle everything from minor repairs to full servicing, ensuring your equipment runs smoothly and minimizing downtime in your operations.

Absolutely! We provide a complete range of spare parts for all the pallet trucks and stackers we sell. Whether you need replacement wheels, hydraulic pumps, or any other part, we have you covered with quality parts to keep your equipment in top condition.

If your pallet truck or stacker experiences a breakdown, simply reach out to us for fast and reliable repair services. We offer on-site or off-site repair solutions, and our team can quickly diagnose and fix issues to get your equipment back in operation. Plus, with our extensive spare parts inventory, we ensure repairs are completed without unnecessary delays.

Not Sure Which Equipment Will Work Best? Let Our Specialist Guide You to the Perfect Fit!